In order to ensure the authenticity and validity of the atomization area temperature and pressure relief safety test results of vape products, after receiving the submitted samples, the inspection and testing agency must check whether the atomization area temperature and pressure relief safety samples produced meet the testing requirements. and confirm. After inspection, it is confirmed that samples that meet the requirements are produced, and a “Testing Entrustment Agreement/Contract” is signed with the customer; if samples that do not meet the requirements are found during the inspection or testing process, the relevant companies are promptly notified and the reasons are explained, the sample return process is entered, and relevant Provincial tobacco monopoly bureaus and technical evaluation centers. In order to avoid unnecessary waste, companies are reminded to pay attention to the following matters when making samples:

1. Temperature sample of atomization area

— Smoking devices or cartridges that are not filled with e-liquid should be used;

— The bonding position of the thermocouple should be at the highest temperature position of the heating element and the bonding should be firm;

— The hardware (including but not limited to heating elements and supporting smoking accessories) and software (including but not limited to control programs) of the samples submitted for technical review (including review materials) should be consistent.

2. Pressure relief safety samples

— It should be consistent with the battery identification used in the samples submitted for technical review (including review materials) (including but not limited to battery model, battery capacity, manufacturer, production date or batch number);

— The battery should not have quality problems such as bulges or leakage, and should not undergo abnormal processing (including but not limited to aging, overcharging, and over-discharging);

— The protection circuit should be bypassed, and no protective components should be added;

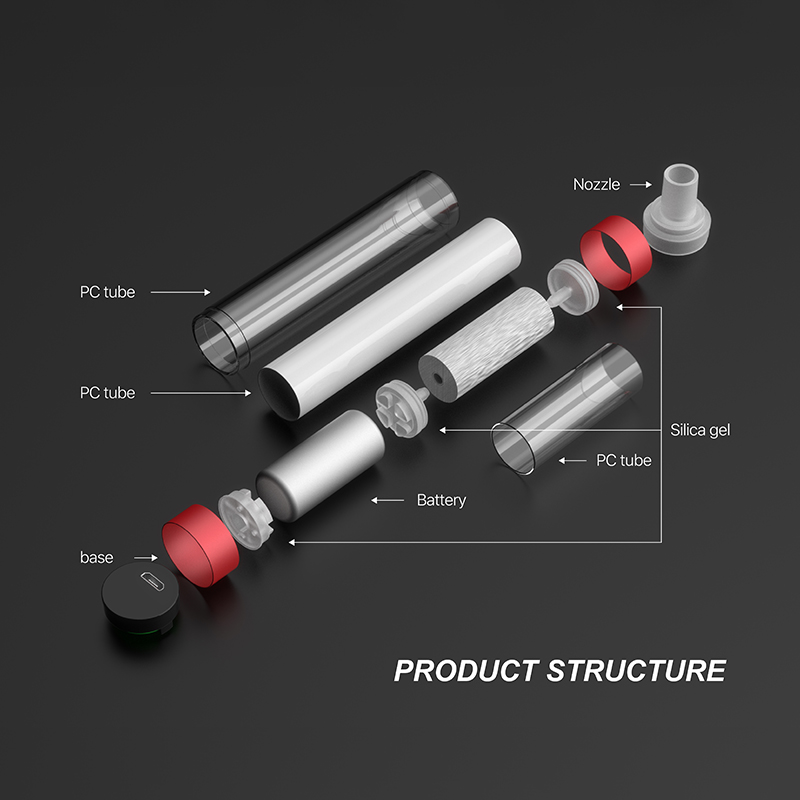

— The internal component composition and battery installation position of the samples submitted for technical review (including review materials) should be consistent.

As an vape brand that focuses on quality and safety, Veehoo vapes always puts the health and satisfaction of its customers first. In order to ensure the quality and safety of its products, Veehoo always pays attention to the latest official authoritative reports and conducts temperature and pressure relief safety tests in the atomization area to ensure the authenticity and validity of the test results. In addition to relying on inspections from external agencies, Veehoo also pays close attention to the latest research reports and conducts self-inspections to ensure product quality consistency and transparency.

Tags: vape pressure relief safety test,How often do pressure relief valves need to be tested,How do you test for pressure relief,veehoo vape